| Holtec International and Westinghouse Electric Company today jointly announced they have signed a 10-year teaming agreement to provide pool-to-pad services to U.S. nuclear sites using Holtec’s dry cask spent fuel storage technology.

With this new teaming agreement, U.S. customers will benefit from Westinghouse’s experience as the industry leader in dry storage canister welding, coupled with Holtec as the original equipment manufacturer (OEM) service provider. The combination offers cross-qualified experienced crew members to meet the growing demand for dry storage resources.

“Dry cask storage is now a critical process in both operating and decommissioning nuclear plants,” said Westinghouse Americas President, Mark Marano. “By combining Holtec’s OEM technical leadership and loading experience with Westinghouse’s long service history and industry leading cask welding experience, our customers will benefit from a strong team that will deliver safe, predictable loading services.”

“The safe storage of spent nuclear fuel is a mission critical to our customers and to the power needs of our country. Without dry fuel storage freeing space for in-pool storage, nuclear plants would not be able to continue operations. This team will deliver the skill sets needed for error-free handling and dry cask storage of the nuclear industry’s spent fuel,” stated Steven Soler, director of Site Services for Holtec International.

Holtec’s Senior Vice President of Operations, PK Chaudhary, added, “Holtec’s arrangement with Westinghouse presents a suite of services that adds value to our clients’ investment in spent fuel dry cask storage with both superior performance and improved economics.”

Westinghouse has successfully welded more than 650 spent fuel canisters since 2002, now averaging over 100 canisters processed each year. Westinghouse’s global workforce includes highly skilled technical and craft personnel with significant dry cask experience and focus on safety, quality and delivering consistent results.

Westinghouse Electric Company, a group company of Toshiba Corporation (TKY:6502), is the world's pioneering nuclear energy company and is a leading supplier of nuclear plant products and technologies to utilities throughout the world. The Westinghouse nuclear business supplied the world's first pressurized water reactor in 1957 in Shippingport, Pa., U.S. Today, Westinghouse technology is the basis for approximately one-half of the world's operating nuclear plants, including more than 50 percent of those in Europe.

Holtec International is an integrated technologies enterprise providing innovative solutions, equipment, and services to the global energy industry. Specializing in spent nuclear fuel management technologies, Holtec has literally changed the landscape of dry spent nuclear fuel storage by designing, licensing, fabricating, and constructing the first underground spent fuel storage facilities in the world. Holtec also provides design, turnkey delivery, problem resolution, life extension, and life assessment services on the entire range of heat exchangers for the electric power generation industry worldwide. Over 770 Holtec dry spent fuel storage systems are loaded in the U.S. and Spain, over 200 loaded by Holtec’s Site Services team. |

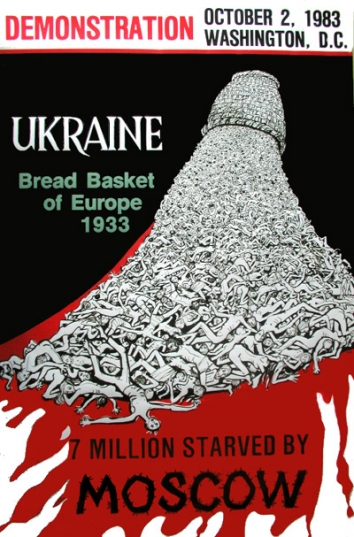

Holodomor Posters

Holodomor Posters

Holtec International, Marlton, NJ

Holtec International, Marlton, NJ