Bolstering Public Health & Safety by Proto-Prompt Decommissioning of Closing Nuclear Plants

Holtec International, Marlton, NJ

Holtec International, Marlton, NJ

Mon, Jan 23, 2017

|

The risk of an accidental pool drain-down precipitating the dreaded specter of zirconium fire, while non-credibly improbable, stalks the decision-making process of every nuclear plant owner preparing to draw down its work force after ceasing operations. Addressing this concern has led Holtec to develop the proto-prompt decommissioning strategy, which we are pleased to unveil below in this news bulletin. The proto-prompt decommissioning envisages conversion of the plant to green field in roughly 5-1/2 years after a reactor's shutdown. Meeting this ambitious schedule requires that the pool be defueled by transferring its used nuclear fuel to dry storage in no more than 2-1/2 years after the reactor's shutdown.

We are pleased to announce that the above rapid de-fueling schedule is eminently achievable, thanks to the friction-stir welded Metamic HT fuel basket, first licensed by the NRC in 2008. The Metamic HT basket (see photo on this page) has over ten times the thermal conductivity of the conventional stainless steel fuel baskets, making it possible to keep the "young & hot" used fuel's temperature below NRC's mandated limits (specified in NRC's ISG11 Rev 3). In short, Metamic HT (a nano-tech product) has shortened the required cooling period of used fuel (prior to transfer to dry storage) from (the previous benchmark of) 7 years to 2-1/2 years, enabling the shuttered plant site to be returned to its pre-plant state in about 66 months after the reactor's shutdown. Now this is a transformative innovation that has a direct and salutary effect on public health and safety!

Sadly, the chronicle of every decommissioning project thus far has been years, even decades, of delay with accumulating upkeep costs and a risky reliance on the trust fund's appreciation in the inherently volatile capital markets to finance the project. The proto-prompt decommissioning strategy espoused herein will eliminate the fuel and high level waste as the obstacle to demolishing the plant and restoring the site for other productive purposes on an expedited calendar. We like to call it a cutting-edge fuel storage technology in the service of accelerated environmental cleanup!

|

|

|

|

A Typical Superb Heat Dissipater Fuel Basket Made from Metamic HT,

Manufactured at Orrvilon, Ohio

|

|

|

|

|

|

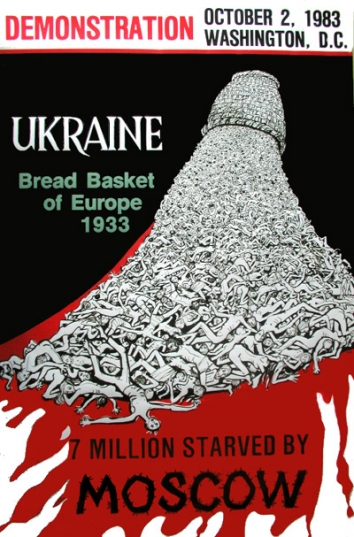

Holodomor Posters

Holodomor Posters

Holtec International, Marlton, NJ

Holtec International, Marlton, NJ